In high-precision manufacturing processes such as impregnation, coating, and laminating, the consistency of material feeding is the foundation of product quality. As an essential component of the production line, the unwinder plays a pivotal role in managing rolled materials. At Yitong Intelligent Equipment, we understand that an Energy Saving and Efficient production process starts with the right material handling solutions.

1. Superior Tension Control and Material Stability

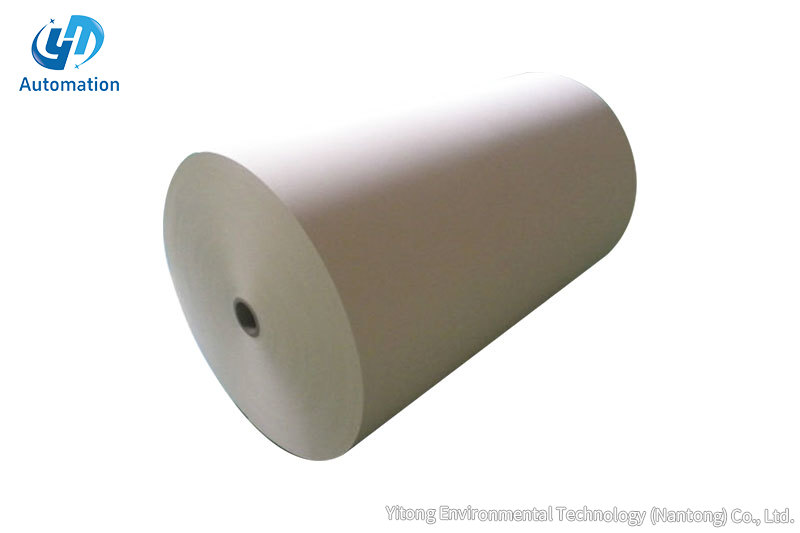

The primary benefit of integrating a high-quality unwinder is its ability to provide precise tension control. Whether you are dealing with paper, films, or technical textiles, maintaining a constant tension is critical to prevent stretching, wrinkling, or breaking of the substrate.

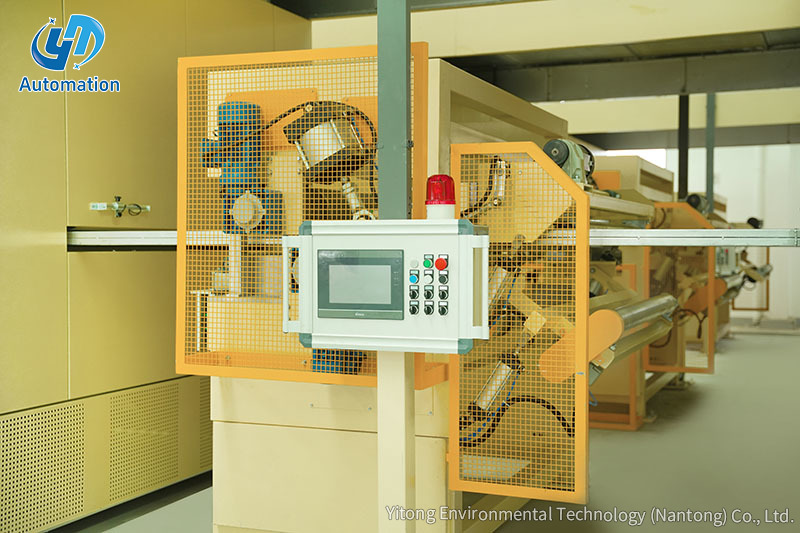

Yitong Environmental Technology (Nantong) Co., Ltd, a leading manufacturer specializing in impregnation and coating equipment, designs its unwinder systems to synchronize perfectly with the rest of the machine. This ensures that even at high speeds, the material enters the coating or drying stage with absolute stability, significantly reducing waste.

2. Enhanced Production Efficiency and Speed

In a competitive industrial landscape, Energy Saving and Efficient operations are the keys to profitability. A manual material changeover can cause significant downtime, cooling of drying ovens, and lost labor hours.

By using an advanced unwinder, particularly those equipped with automatic splicing capabilities, factories can achieve continuous production. This means your impregnation or coating line doesn't have to stop when a roll ends, allowing for a seamless transition that maximizes throughput. Yitong Intelligent Equipment focuses on these automated solutions to help clients in the furniture and construction sectors boost their daily output.

3. Precision Alignment with Edge Guiding Systems

Material "telescoping" or drifting is a common issue when dealing with large rolls. A professional unwinder is often equipped with integrated edge sensors and guiding systems. This ensures that the material is always fed straight into the machinery.

For industries like electronics and automotive, where precision is non-negotiable, the alignment provided by the unwinder prevents edge coating defects and ensures that every millimeter of the material is utilized correctly, embodying the environmental philosophy of Yitong Environmental Technology (Nantong) Co., Ltd.

4. Versatility Across Multiple Industries

One of the standout features of the unwinder units produced by Yitong is their versatility. Our expertise allows us to provide advanced solutions across a wide range of industries, including:

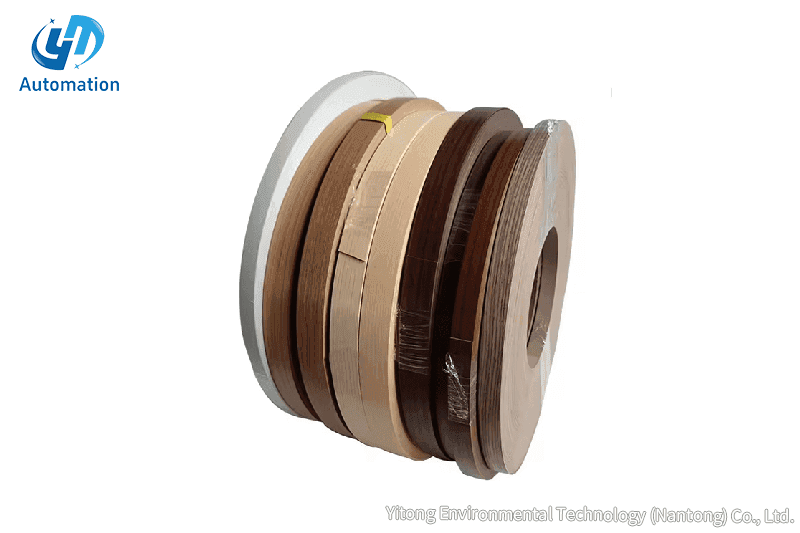

- Furniture & Construction: For the impregnation of decorative paper used in laminates.

- Automotive: For coating materials used in interior components and heat shields.

- Electronics: Handling delicate films for circuit board manufacturing.

Why Choose Yitong Intelligent Equipment?

With years of expertise, Yitong Environmental Technology (Nantong) Co., Ltd has established itself as a pioneer in the field of impregnation, coating, and drying equipment. Our unwinder solutions are not just accessories; they are engineered to be Energy Saving and Efficient, reducing the carbon footprint of your manufacturing facility while increasing your bottom line.

About Yitong

Yitong Environmental Technology (Nantong) Co., Ltd is a leading manufacturer specializing in impregnation, coating, and drying equipment. With years of expertise, we provide advanced solutions for impregnation, coating, and drying processes across a wide range of industries, including furniture, construction, automotive, electronics, and more. Our commitment to Yitong Intelligent Equipment ensures that every customer receives a high-performance, durable, and sustainable machine.

Conclusion: The ROI of a Professional Unwinder

In conclusion, when asking what the benefits are, the answer lies in the total cost of ownership. A high-quality unwinder reduces material waste, lowers energy consumption during restarts, and ensures a superior final product. If you are looking to upgrade your production line with Energy Saving and Efficient technology, Yitong is your trusted partner.

Ready to Optimize Your Production with a Yitong Unwinder?

Contact Our Technical Experts Today